Novastar’s new COEX Control System is here, and it’s got top-notch video processing and cool image upgrades. With full-grayscale calibration, dynamic booster, and thermal compensation, it makes every detail and color pop. It also handles color correction, shutter sync, phase offset, and frame multiplication, so it’s perfect for xR virtual shoots.

This will guarantee that every video capture will be seamless and flawless. On top of that, with NovaStar’s brand new VMP (Vision Management Platform), the solution combines the quaternity of design, debugging, management, and monitoring into one package. Managing the display system has never been this efficient and convenient.

What we need for bringing these features to an account?

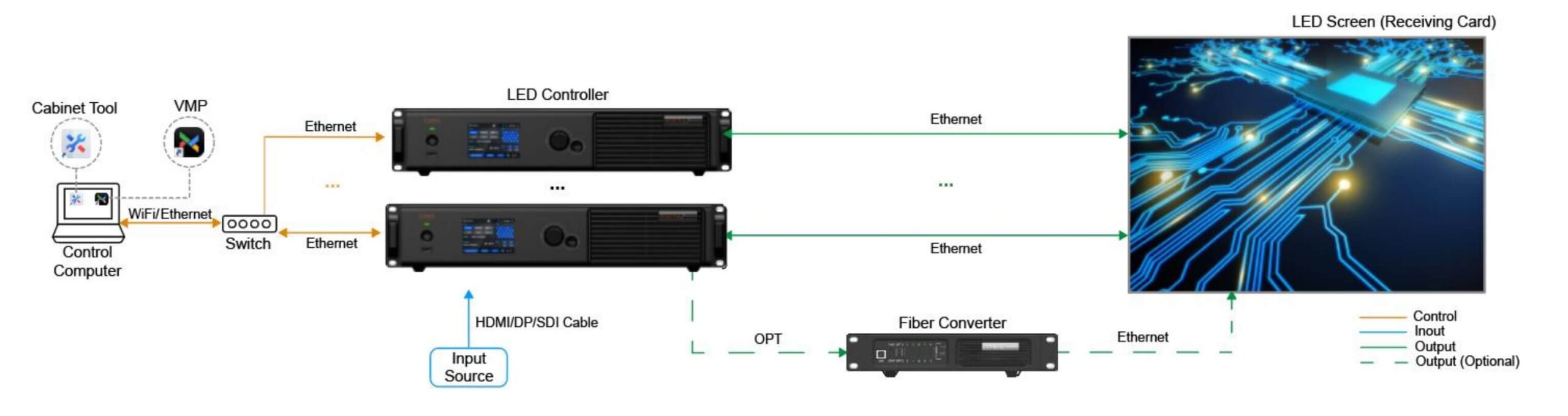

| Component | Description |

| LED controller | 1G: MX40 Pro, MX30, KU20 5G: CX80 Pro, CX40 Pro |

| Receiving card | 1G: Armor series receiving cards such as A10s Pro, A10 Plus-N, A8s-N, A7s Plus, A5s Plus 5G: CA50E, CA50C, XA50 |

| Fiber Converter | 1G: CVT10 Pro, CVT10 5G: CVT8-5G |

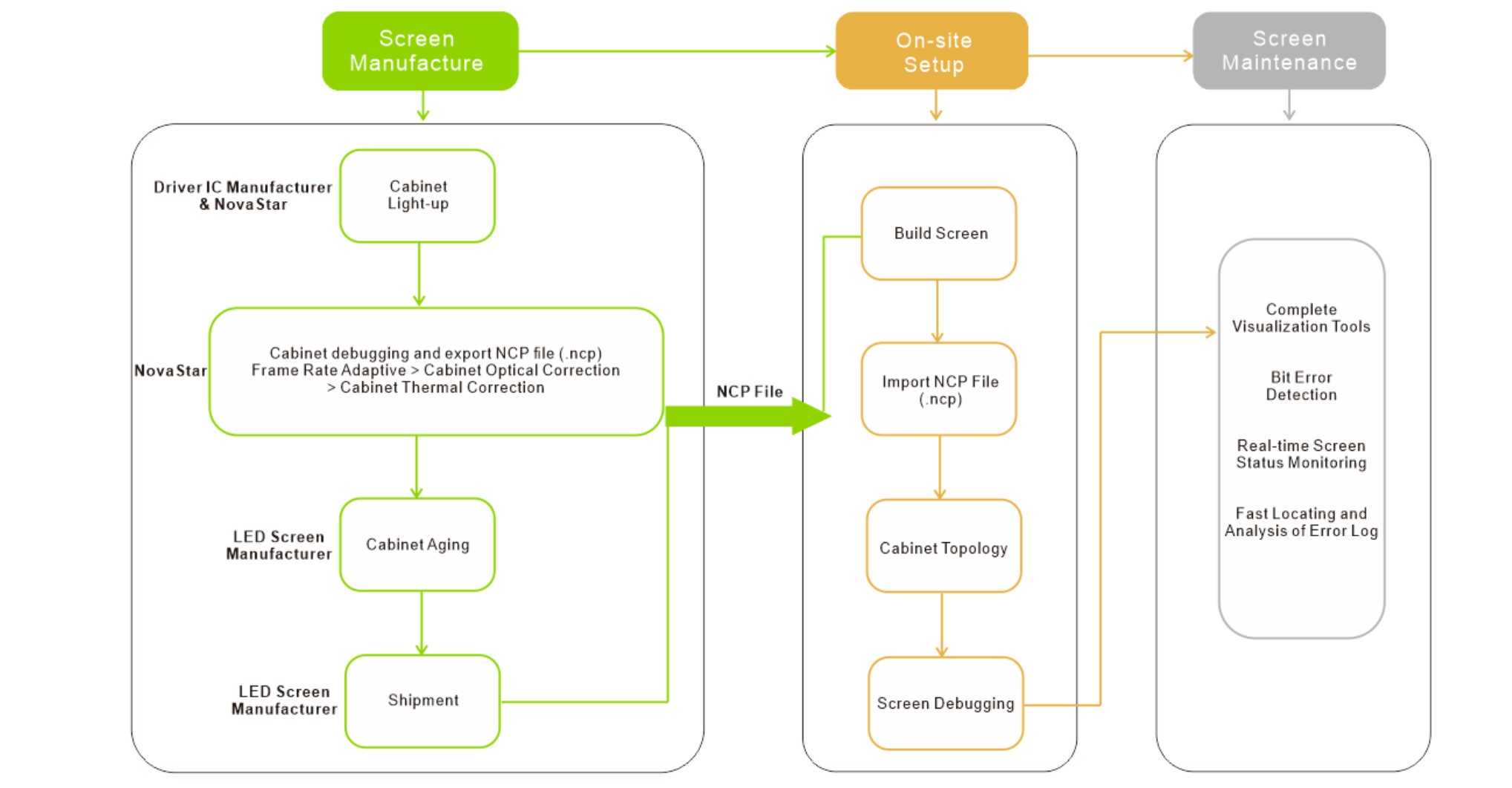

NCP File Introduction

The NCP file packs six features into one: cabinet setup, firmware, image boost, frame rate adjustments, mode settings, and thermal correction. Just upload this file from your computer or load it into the control system, and you’re set to get the best display with just a few clicks.

To create an NCP file using the Cabinet Tool, contact LEDResQ tech support. We collaborate with NovaStar to provide the NCP file.

Question:

Can I keep using my current screen after switching to a COEX controller?

You can switch to a COEX controller and keep using your current screen. If you experience a display issue after the switch, you may follow the instructions listed below depending on whether you have an NCP file:

I have an NCP file

- Import NCP file: Select Tools > Maintain from the VMP toolbar and then import the NCP file on the Cabinet screen.

- Edit NCP file: If the current NCP file does not meet your requirements, please contact

- LEDResQ support engineers will modify and provide an updated NCP file in collaboration with novastar.

I don’t have an NCP file

- Import. rcfgx file: Select Tools > Maintain from the VMP toolbar and then import the. rcfgx file on the Cabinet screen.

- Edit. rcfgx file: If the current. rcfgx file does not meet your requirements, please switch back to your previous controller and modify the file using NovaLCT. Unfortunately, VMP does not support modifications to. rcfgx file.

- Obtain an NCP file: If you’d like to use the frame rate adaptive (only on supported driver ICs), image booster, or thermal compensation, please contact LEDResQ and NovaStar technical support engineers will provide an NCP file based on your requirements.